About CIIC

- Crescent Innovation & Incubation Council (CIIC) is under the ambit of B.S. Abdur Rahman Crescent Institute of Science and Technology which is deemed to be University under Section 3 of UGC Act 1956.

- CIIC has been established as a Section-8 not for profit company and registered under Indian Companies Act 2013.

- CIIC acts as a “One Stop Shop – Startup Incubator” for startups that facilitates entrepreneurial & innovative ecosystem to all the stakeholders including the Students, faculty members, industries, investors and society at large.

- CIIC is presently focusing on the disruptive technologies in the domains of Life Sciences, Industry 4.0, Smart & Clean Mobility.

Vision

- To become a University based Technology Based Incubator of Excellence with national & international allusion parameters

- To reform entrepreneurial student aspirants into start-up establishment

- To support & render start-up into a profitable entity.

- To transform innovation into scalable business models with high productive impact and also encouraging interdisciplinary advancement.

- To create impact for economic development and community wealth.

Mission

- To recognize and nurture students, faculty members and alumni into early stage startups.

- To create and promote collaborative networks through partnerships between academia, industry and government.

- To increase and advance the in-house operational skills for leveraging entrepreneurial expertise and resource network.

- To identify & nurture top-notch entrepreneurs in Life Sciences, Industry 4.0, Smart and Clean Mobility through expert mentoring and also to foster lean startups to sustainable companies.

Value

To nurture our society by nudging the entrepreneurs with

- Integrity

- Sustainability

- Culture of innovation

- Five 'M' Strategy (Mentor, Money, Market, Machinaries and More)

Impact Created

0

Startups

0

Patents

0

Mentors

0

Awards

0

Jobs Created

0

CIIC Grants Received (Rs in Cr.)

0

Startups Valuation (Rs in Cr.)

0

Startups Funds Raised (Rs in Cr.)

0

Partners

Highlights

SISFS

MeitY

BIRAC BioNEST

NIDHI PRAYAS

EDII-IVP

MSME LBI

Fisheries Challenge

HDFC and DBS CSR

StartupTN

Our Services

Thrust Areas

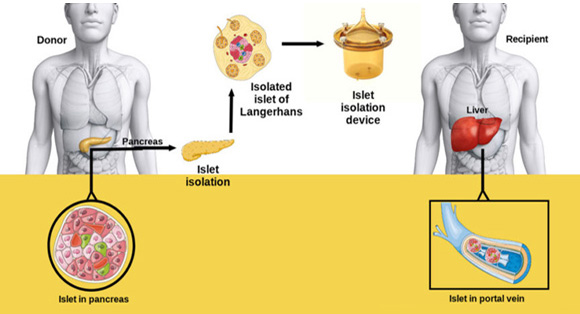

- LIFE SCIENCES

(Agri-Tech, Med-Tech, Bio-Energy, Bio-Pharma, Bio-Services, Bio-Industrial) - INDUSTRY 4.0

(AR/VR, System Integration, Simulation, Big Data, Autonomous Robot, Cloud Computing and IOT) - SMART & CLEAN MOBILITY

(Drone Technology, Smart & Non Fossil Fuel Vehicles, Electric Vehicles, EV Battery Management and Autonomous Navigation)

Advanced Entrepreneurship Courses

- MBA in Innovation, Entrepreneurship and Venture Development

- Intel Program - RAI (Robotics, Artificial Intelligence, IoT )

- Special Program

Facilities

- Rs. 10 Lakh worth free online tools

- Office space / Lab space

- Marketing Services

- Training & workshops / seminars

- Legal services / IPR services

- Connect with investors

- Access to seed funding

- Industry connect

Thrust Areas

- LIFE SCIENCES

(Agri-Tech, Med-Tech, Bio-Energy, Bio-Pharma, Bio-Services, Bio-Industrial) - INDUSTRY 4.0

(AR/VR, System Integration, Simulation, Big Data, Autonomous Robot, Cloud Computing and IOT) - Mobility and Transportation

Entrepreneurship Courses

- MBA in Innovation, Entrepreneurship and Venture Development

- Social Entrepreneurship by Wadhwani Foundation

- Life Sciences Innovation & Entrepreneurship

- Certified Chief Innovation Officer (CCIO) by Rocheston, US

Facilities

- Rs. 10 Lakh worth free online tools

- Office space / Lab space

- Marketing Services

- Training & workshops / seminars

- Legal services / IPR services

- Connect with investors

- Access to seed funding

- Industry connect

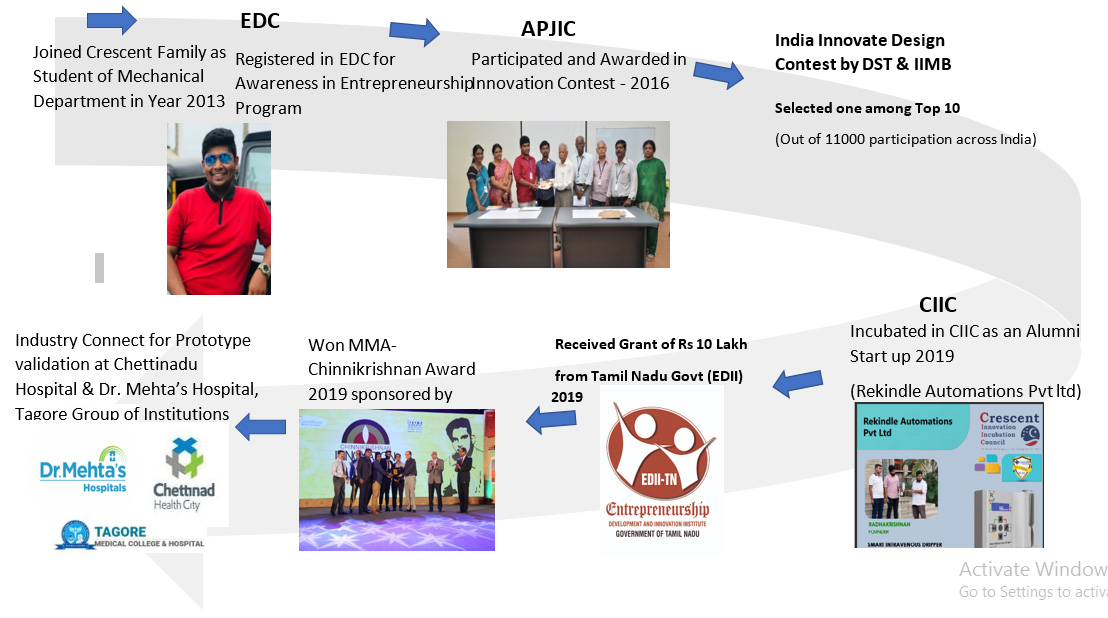

Testimonials by our startups

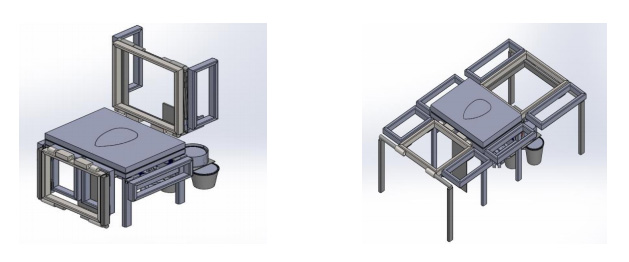

We, KARDLE Industries, are a healthcare and life science startup developing Next gen Bioreactors and Air process systems. We are glad to be incubated at CIIC, as CIIC has mentored, guided and helped us receive government Grant's to pilot our product. CIIC is also serving as the best support to test, demonstrate and implement new technologies we have developed in recent days. We see CIIC as one of our best facilitators.

Mr. Vijay Komagan M.S Director,

Kardle Industries Pvt. Ltd.

Confidence to entrepreneurs to pursue their dreams offering its network

Innovation in operational model aligned to evolving dynamics

Integrity in its open book approach

Capital for entrepreneurs to realise their potential through various avenues

Combined together shines CIIC forever

Mr. Ravi Senji, Founder,

Agrifacture India Pvt. Ltd

“MirrAR is an AR/VR/MR deep tech startup and have developed proprietary Virtual Try On solution that works on a browser. We are incubated nearly from the inception of the at CIIC and we see CIIC as one the top most incubators in the country. They have a solidly built a huge network with a very strong and eminent team who are always supportive. They are instrumental in our growth journey and we are really thankful to them.”

Mr. Jayaprakash Founder and CEO

Mirrar Innovation Technologies Pvt Ltd

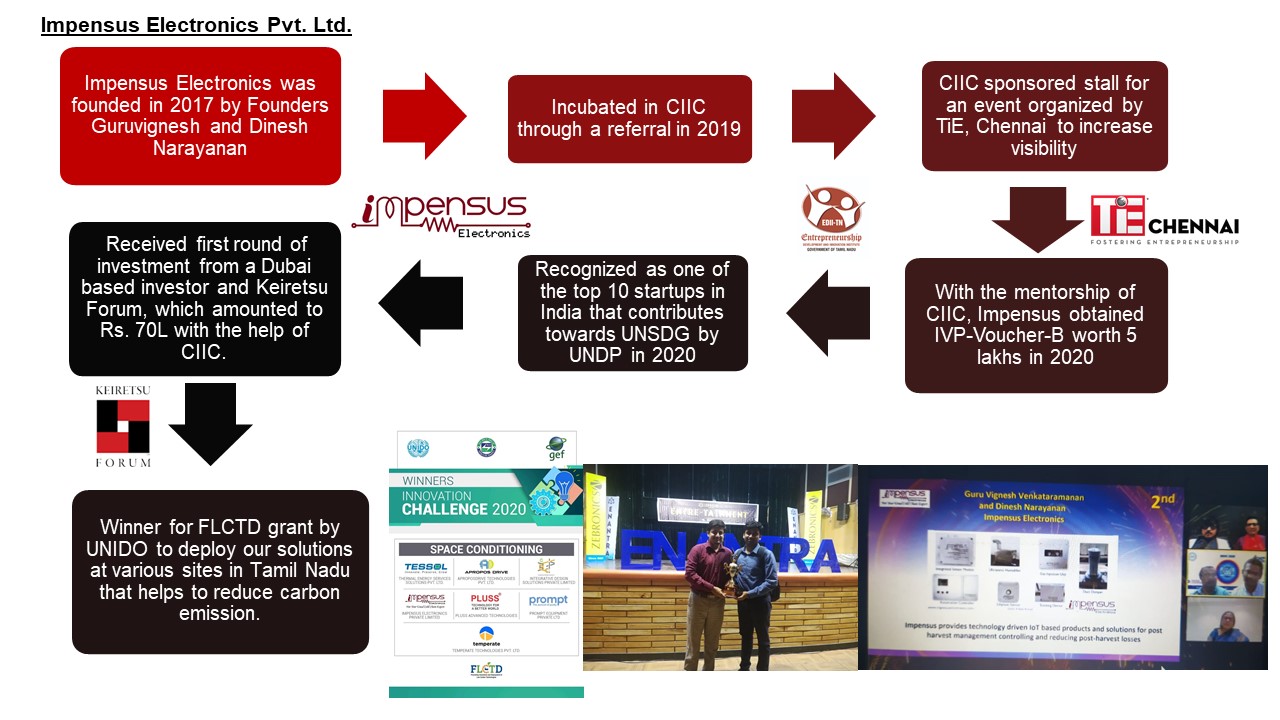

During our initial days, when we were looking to shift our office from Madurai to some other place, we got introduced to CIIC through our mentor and that's how our association with CIIC started. CIIC has provided us with office space - we're even expanding now, helped in IVP vouchers and other grants. CIIC is also instrumental in pushing our solutions for mushroom cultivation, the tremendous response which we are seeing now. One of the biggest things is that through CIIC we got introduced to our investors and because of that, private investors and networks like Keiretsu Forum have invested in our company. We would like to thank CIIC for the support extended and would like to have a long standing relationship.

Mr. Dinesh Co-Founder,

Impensus Electronics Pvt. Ltd.

We got all help from CIIC right from our idea validation stage and got transformed into a startup. The workspace, mentorship, investor connections and above all the smart internship students were very important and helpful for us. All Startup incentives relevant to our startup, Govt grants, and hundreds of free premium technology costing thousands of dollars like AWS, Azure, Digital Ocean, Zoho were recommended and made available for us at no cost. The entire CIICs team's swift and smart action updati\ed and availed facilities immediately when it got announced. It makes a lot of difference for startups like us and gives the global competitive advantage. After all, we survived with CIIC business network, overseas leads, exhibitions and promotional activities.

Mr. SURLI KANNAN,

Founder Iviewsense Pvt. Ltd.

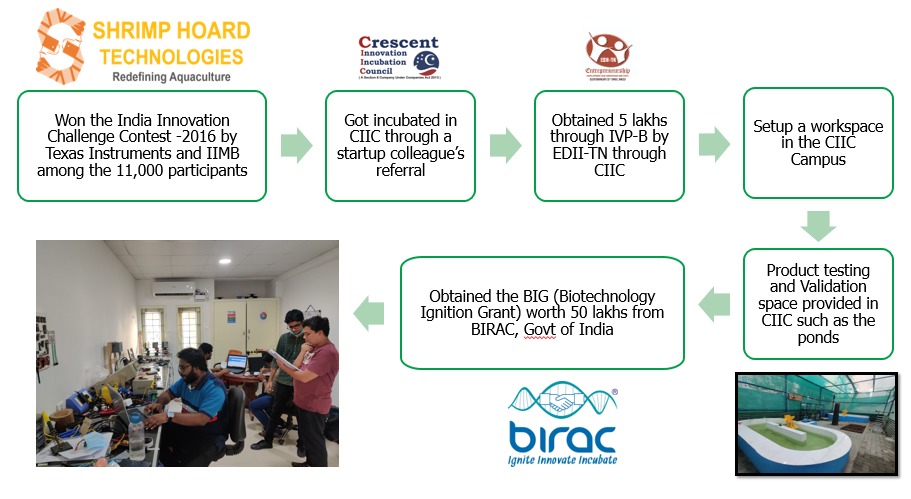

It’s been a great journey here at Crescent Innovation and Incubation Council since I stepped in looking for a working space. But since then we have been able to achieve a few milestones which particularly happened with the support of CIIC. To name a few we had been able to get a seed grant from EDII under the Voucher B category, through CIIC’s enormous network we had been able to grab in some potential customers who have been helping us out in doing our field trials. The ecosystem here has been very overwhelming with testbeds being provided for most startups in-house.

CIIC has been able to grow at such a fast pace and with all the necessary infra and support for their startups within a short span of 2 years and I feel there are very few incubation centers out there who have been able to onboard such a huge chunk of startups and partnerships.

Sushil Paul,

Founder, Shrimp Hoard technologies

Crescent Innovation and Incubation Council is one of the best Bio-incubators in Chennai with perfect ambience for emerging entrepreneurs with best mentoring support.

Ms. Kavitha Madhusudhanan,

Director, HAIN Biosolutions

CIIC is harbored with a team of experts in various fields and also has excellent marketing strategies. Being a Biotech startup, their Bio-NEST laboratory facility have been very much useful for Research and Development purposes.

Prashanth K K,

CEO & Director - SIMBIOEN Labs and Scientific Services Private Limited